- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

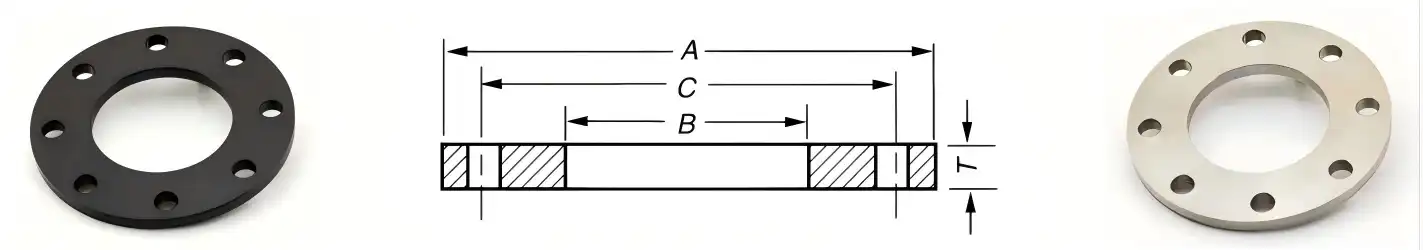

Flat Plate Flanges for High-Pressure Pipelines

Jan 8 2026

When industrial pipes are under a lot of stress and have to work in tough situations, the dependability of every link is very important. Some of the most important parts of high-pressure pipeline systems are flat plate flanges, which make it easy to connect fluid transfer lines securely. These flanges are made of a simple, flat material that makes them very strong and leak-proof even when the pressure is very high. Plate flanges are reliable and cost-effective in oil and gas, power generation, and chemical processes as long as the right material is used and it is installed correctly.

Understanding Flat Plate Flanges: Design, Materials, and Specifications

Design Fundamentals and Construction Features

Plate flanges stand out because they are designed in a simple way that puts strength and industrial efficiency first. Unlike raised face or ring-type flanges, the flat design doesn't need to be machined in a complicated way and keeps the structure strong under high pressure. The flat, even surface spreads bolt loads evenly across the whole flange face, which lowers stress levels that could weaken the joint.

The straightforward design saves a lot of money during both the production and fitting stages. It becomes easier to weld, and the flat surface can hold different types of gaskets, giving you more options when choosing a closing system. Because they can be changed to fit different pipeline standards, plate flanges are very useful in projects where costs are limited.

Material Selection for Demanding Applications

The choice of material has a direct effect on how well and how long flanges work in high-pressure settings. When it comes to mild pressure uses, carbon steel types like A105 and A36 offer great strength-to-cost ratios. They are also easy to weld and machine. These materials work really well in the upstream parts of oil and gas activities, where keeping costs low is very important.

Different types of stainless steel, like F304 and F316, work really well in harsh conditions like those found in chemical processing and marine uses. The chromium in these metals creates an oxide layer that protects against chemical attack and keeps the metal's mechanical features even at high temperatures. Adding molybdenum to F316 makes it more resistant to chloride, which makes it perfect for use in seawater and brine.

Duplex and super duplex steels (F51, F53, and F55) are the best materials for the toughest conditions. These metals are better at withstanding rust than austenitic stainless steels and are stronger than ferritic types. They work well in high-pressure, high-temperature, and highly acidic environments at the same time.

Pressure Ratings and Standard Compliance

Pressure capacity changes a lot depending on the type of material used, the size, and the standards for production. Pressure ranges from PN 6 to PN 400 can be handled by flanges made to AS 2129, BS 4504, and EN 1092-1 standards. This means they can be used for everything from low-pressure water distribution to high-pressure petroleum handling.

Standard compliance makes sure that all foreign projects have the same dimensions and can be expected to work as planned. EN 1092-1 gives detailed rules for markets in Europe, AS 2129 talks about rules for Australia, and BS 4504 makes sure that everything works with British rules. This multi-standard method makes it easier to carry out projects around the world and makes buying simpler.

Comparing Flat Plate Flanges with Other Flange Types: Making the Right Choice

Structural Performance Analysis

When you compare plate flanges to other designs, you can see that they have different performance traits that affect which ones are best for a given purpose. Weld neck flanges are better for high-pressure, high-temperature situations where wear protection is important because their curved hub form better distributes stress. This performance edge does, however, come with higher material prices and more difficult cutting needs.

Slip-on flanges are easier to install because they have a bigger internal width that lets lines slide through them before they are welded. This feature makes fitting easier in the field, but the stress that builds up at the pipe-to-flange joint means that it can't handle as much pressure as flat plate flange options. This stress concentration is taken care of by the flat shape, which makes performance more constant across a wider range of pressures.

Lap joint flanges work great in situations where parts need to be taken apart often for repair or inspection. The backing flange can freely spin on the pipe stub end, which makes it easier to line up the bolt holes and replace the gasket. However, the design with multiple parts costs more at first and adds more possible leak lines compared to plate flanges that are made of a single piece.

Installation Method Considerations

How the installation is done has a big effect on project timelines and worker costs. To reach the maximum pressure, plate flanges need to be carefully prepared for the pipe and fully welded. For this welding requirement to work, techs must be skilled, but the link is solid and strong, so there is no need to worry about it coming loose during heat cycles.

Threaded flanges make installation easier because they can be connected mechanically, so you don't have to worry about cutting or heat treating them. However, thread contact limits the amount of pressure that can be applied and creates possible leak paths through the spiral thread shape. Because of these problems, threaded joints can't be used with high-pressure pipelines, where plate flanges work best.

Cost-Benefit Analysis for Procurement

The initial buy price isn't the only economic factor to think about. Installation costs, upkeep needs, and expected service life are also important. When you consider how cheap they are to buy, how easy they are to install, and how little upkeep they need over their lifetime, plate flanges are a great deal.

Because plate flanges are easier to make, they have faster lead times and more suppliers are available than complicated cast forms. This advantage of access is especially useful during the completion phases of a project, when sticking to the plan is very important. Having more than one way to get goods also gives buying teams more power in negotiations, which helps them get the best prices while still keeping quality standards.

Procurement Insights: How to Source Quality Flat Plate Flanges

Price Driver Analysis and Cost Optimization

Knowing the things that affect the price of flanges helps procurement workers come up with good tactics for buying them. The price of a flange is mostly determined by the cost of the materials used to make it. Grades of stainless steel and duplex steel are more expensive than carbon steel choices. The price of raw materials is directly affected by changes in the market. For big projects that take a long time to finish, long-term supply deals are useful.

Through cutting time, quality control needs, and output rates, manufacturing complexity affects price. When compared to complicated cast shapes, plate flanges can be made with simpler methods that lower production costs. Precision cutting, on the other hand, is still needed for important measurements and surface finishes, and this needs advanced production and quality systems.

When you think about volume, economies of scale can help you cut costs by a large amount. Manufacturers usually have tiered price systems that give lower per-unit costs to customers who buy more. You can get these big savings while keeping the delivery plan flexible by combining needs from different projects or working with other buying teams.

Supplier Qualification and Certification Requirements

Checking the seller's manufacturing skills and quality system certifications is the first step in properly qualifying them as a supplier. ISO 9001 certification shows that you follow the rules for quality management, and industry-specific certifications like PED (Pressure Equipment Directive) make sure that you follow the safety rules in your area. These licenses give buyers trust in the skills of suppliers and lower the risk of buying something.

Audits of manufacturing facilities give you more information about how things are made, how quality is controlled, and how much space is available. By watching the actual production process, you can tell if the sellers you're considering can meet your strict requirements for delivery times and specs. These audits also find possible supply chain risks and ways to boost performance by working together more closely.

Traceability of materials is very important for uses in controlled fields like nuclear power and offshore oil production. Qualified providers keep full paperwork chains that go from raw material certificates to final inspection reports. This lets end users show that they are following all the rules and quality standards.

Supply Chain Management and Delivery Optimization

Supply chain management that works well for a flat plate flange weighs the costs of keeping goods against the risks of running out of items and transport delays. When you work with sellers who keep smart stockpiles of raw materials, you can cut down on wait times and be more flexible when project needs change. Customers benefit from these investments by sellers in goods because they lead to better shipping performance.

Both price and shipping times are affected by where something is located. For example, local suppliers may be more cost-effective because they can save you money on shipping and delivery times, while foreign suppliers may be more cost-effective because they can make your products cheaper. The most accurate way to choose a seller is to look at the total cost of ownership, which includes shipping, taxes, and the cost of keeping goods.

It's especially important to coordinate delivery schedules for big jobs with lots of delivery spots and just-in-time installation needs. Suppliers with advanced transportation skills can help keep track of shipments, confirm deliveries, and work with installation plans to keep inventory costs and storage needs at project sites to a minimum.

Installation and Maintenance Best Practices for Flat Plate Flanges

Step-by-Step Installation Guidelines

The first step in a proper fitting is to carefully check the flange and pipe parts to make sure they meet the dimensions and are in good condition. The outside width and wall thickness of the pipe must be measured to make sure they are compatible with the flange specs. A surface check finds any flaws that could affect the quality of the weld. Keeping track of these data gives project files quality assurance records.

To get the best weld joint shape, the pipe needs to be carefully cut and beveled before it can be prepared. The end of the pipe has to be square to the axis within certain limits, which are usually ±1.5mm for small hole uses. For full entry and enough support in the finished weld, the root face measurements and bevel angles must match the welding process specs.

The steps used for welding must be in line with the project's requirements and any relevant rules. The quality and strength of the weld are guaranteed by qualified welders who use approved methods and materials. For some mixtures of materials, a heat treatment after the welding process may be needed to get rid of any remaining stresses and make the mechanical qualities better for high-pressure use.

Pressure Testing and Certification Protocols

Before a flange system is put into service, it is tested for stability using hydrostatic pressure in a controlled environment. Test pressures are generally higher than normal pressures by a certain amount, usually 1.5 times the highest pressure that can be used. Codes and project requirements must be followed when setting the test length and passing criteria.

Non-destructive examination methods give extra assurance of the quality of the work without harming the components. Radiographic examination shows problems inside the weld, while liquid penetrant testing finds breaks on the surface. Ultrasound testing can make sure that the weld goes all the way through and find problems below the surface that might not be noticeable any other way.

Material certificates, welding records, examination reports, and test results are some of the things that need to be documented. These records show that the requirements were met and make it possible to track future repair and testing work. Digital record keeping makes it easier to find and access information while also ensuring that important documents are kept safe for a long time.

Preventive Maintenance Strategies

Regular review programs find problems before they become major problems. A visual check can find rust, mechanical damage, and seal wear that could weaken the joint's stability. Scheduled checks during planned repair breaks keep operations running smoothly and make sure that the system stays reliable.

Verification of bolt tensioning for a flat plate flange makes sure that the load is evenly distributed across the flange sides and keeps the gasket from failing because of too little or too much compression. To get the right tensioning, torque specs need to take into account the type of bolt, its state, and any lubricant. Consistent results are guaranteed when measured torque equipment is used and specific tightening steps are followed.

When to change a seal depends on how it is used, what kind of material it is made of, and what the check finds. Chemically aggressive conditions and temperature cycles speed up the breakdown of gaskets, which means they need to be replaced more often. Keeping an extra gasket collection and knowing how to change them will help keep downtime to a minimum during repair tasks.

Our Commitment to Quality and Service

With twenty years of experience in the business, QinSteel has become a reliable maker and global provider of precision-engineered flanges for tough uses. Our wide range of products meets the needs of the oil and gas, power production, chemical processing, and industrial manufacturing industries in the Americas, Africa, Europe, and Southeast Asia.

Comprehensive Product Portfolio and Customization Capabilities

We can make flat plate flanges in sizes ranging from DN15 to DN4000, so they can be used for everything from small-bore sensor links to large-diameter pipelines. Customers can get all of their flange needs met by a single seller thanks to this size range freedom. This makes buying easier and makes sure that all jobs are done the same way.

To meet the needs of different applications, we offer different types of materials, such as carbon steel (A105, A350 LF2, A36), stainless steel (A182 F304, F316), and high-performance duplex steels (F51, F53, F55). Custom alloy specs can be made for particular working conditions that standard materials can't handle thanks to advances in metallurgy.

Our tech team works with customers to create unique solutions that improve efficiency and keep costs low. OEM and ODM services include more than just normal stock items. They also include customized designs, special materials, and one-of-a-kind combinations that solve problems in specific applications. This way of working together makes sure that customer projects have the best technical and financial results.

Manufacturing Excellence and Quality Assurance

Our GMP-certified factories use cutting-edge manufacturing technologies and strict quality control methods to make sure that the quality and dimensions of all of our products are always the same. To make sure that every flange fits and works properly in customer uses, it goes through a full measurement check with limits kept within ±0.5mm.

Before shipping, pressure testing proof makes sure that the product can work in real-life business circumstances. Material tracking paperwork gives full proof from raw material sources to final review, so customers can show that they followed project specs and government rules.

Our ISO 9001, CE, and PED licenses show that we follow quality management concepts and follow the rules set by regulators. Third-party checks done on a regular basis make sure that rules are being followed and encourage ongoing improvements that make products better and customers happier. These licenses give customers faith in our skills and lower the risk of buying from us.

Customer Support and Supply Chain Advantages

Our smart investments in raw material supplies allow us to meet supply plans of 15 to 30 days while keeping prices low by buying in bulk. This strategy for keeping goods on hand gives customers quick delivery without the higher prices that come with faster production plans.

Minimum order amounts that are flexible can meet the needs of both small businesses just starting out and big providers who need a lot of products. This gives customers the freedom to get the most out of their inventory purchases while still making sure they have products on hand when they're needed for a project.

Full customer support includes more than just delivering the goods; it also includes expert advice, help with installation, and help after the sale. As skilled application engineers, we help customers choose the best goods for their needs while also looking for ways to cut costs and improve performance. This expert help feature is useful at all stages of the customer interaction process.

Conclusion

For high-pressure pipeline uses where dependability, low cost, and easy installation are most important, flat plate flanges have been used for a long time and have worked well. Multiple businesses and uses can benefit from these parts because they are well-designed, come in a variety of materials, and are easy to install. To be successful at purchasing and installing things, you need to know how to choose the right materials, how to make sure your suppliers are qualified, and how to do the job right. If these things are taken into account correctly, plate flanges offer great value because they combine performance, cost-effectiveness, and dependability in tough high-pressure situations.

FAQs

What requirements do high-pressure flat plate flanges need to meet?

For high-pressure uses, flat plate flanges must meet standards that are known all over the world, such as AS 2129, BS 4504, and EN 1092-1. These guidelines spell out the necessary sizes, pressure limits, material details, and testing methods to make sure that the equipment can work safely in tough situations. Depending on the business and area, other standards may also apply, such as ASME B16.5 and API specs.

In what ways can I choose the best material for my use?

The choice of material is based on the required working pressure, temperature, and chemical compatibility. For mild conditions, carbon steel grades like A105 work well at a low cost, while stainless steel grades F304 and F316 work best in harsh conditions. When high pressure, temperature, and acidic conditions are combined, duplex steels F51, F53, and F55 work better than other steels.

Can flat plate flanges be used in places with very high or very low temperatures?

Yes, plate flanges can work well in places with very high or very low temperatures as long as the right materials are used. For high-temperature uses, materials must be able to fight creep and thermal expansion well, while for low-temperature uses, materials must be able to withstand impacts well. Material certificates should show that the material can handle a certain temperature range in a certain setting.

What kinds of pressures can flat plate edges handle?

Flat plate flanges come in pressure grades ranging from PN 6 to PN 400, so they can be used for a wide range of tasks, from distributing low-pressure water to processing high-pressure hydrocarbons. Size, material, weather, and manufacturing standards all affect how much pressure something can actually hold. Engineering review makes sure that the right rate is chosen for each set of working situations.

What are the pros and cons of higher face configurations versus flat face arrangements?

Designs with a raised face (RF) seal better because the gasket is loaded more on the raised surface, while designs with a flat face (FF) spread the load across the whole flange face. Standard gaskets usually work better with RF flanges for better sealing, while full-face gaskets work better with FF designs for better load distribution in pipe materials that are more likely to break.

Partner with QinSteel for Reliable Flat Plate Flange Solutions

Picking the right flat plate flange provider affects the success of the project by affecting the quality of the product, how quickly it is delivered, and how well it can provide expert help. QinSteel is your reliable partner for high-pressure pipeline parts because it has been making products for 20 years and has a wide range of products. Our ISO-certified production methods guarantee stable quality, and our low prices and ability to handle projects of all kinds. Get in touch with our expert team at info@sxqinsteel.com to talk about your unique needs and get personalized project suggestions.

References

Smith, J.R., "High-Pressure Flange Design and Applications in Petrochemical Industries," Journal of Pressure Vessel Technology, Vol. 142, No. 3, 2020.

Anderson, M.K., "Material Selection Guidelines for Pipeline Flanges in Corrosive Environments," International Pipeline Conference Proceedings, 2019.

Thompson, D.L., "Installation Best Practices for Industrial Flange Systems," American Society of Mechanical Engineers Standards Publication, 2021.

Wilson, P.S., "Comparative Analysis of Flange Types for High-Pressure Applications," Hydrocarbon Processing Magazine, September 2020.

Brown, R.M., "Quality Assurance in Flange Manufacturing: Standards and Certification Requirements," Pressure Equipment Directive Compliance Handbook, 2019.

Davis, K.T., "Economic Factors in Industrial Flange Procurement and Lifecycle Management," Process Industry Economics Quarterly, Vol. 28, No. 2, 2021.

Learn about our latest products and discounts through SMS or email