- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Carbon Steel Blank Flanges

Xi 'An QinSteel Trading Co., Ltd | Premium Carbon Steel Blank Flanges Manufacturer & Global Supplier

With over 15 years of expertise, we specialize in bulk production and rapid delivery of industrial-grade Carbon Steel Blank Flanges for oil, gas, and heavy-industry applications.

What Are Carbon Steel Blank Flanges?

The products (also called blind flanges) seal pipeline ends, valves, or pressure vessel openings. Built for durability, these flanges withstand extreme temperatures and pressures while preventing leaks. Crafted from ASTM A105, A350 LF2, or custom grades, they comply with ASME, API, and EN standards—ensuring safety in critical systems.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Why Our Carbon Steel Blank Flanges Stand Out?

✅ Global Compliance: Meet API 6A, ASME B16.5, EN 1092-1, and JIS B2220 standards.

✅ Unmatched Range: Sizes from ½" to 144" (DN15–DN4000) for small-bore pipes or large industrial lines.

✅ High-Pressure Ready: Rated up to Class 2500 for demanding environments.

✅ Custom Solutions: OEM/ODM services for unique sizes, materials (e.g., Q235, S235JR), or facings (RF, RTJ, etc.).

✅ 24/7 Availability: Large inventory + regional warehouses in Houston, Dubai, and Singapore.

Applications

- Sealing oil/gas pipelines

- Petrochemical plant maintenance

- Power generation systems

- Shipbuilding & water treatment

Quality Assurance

Every Carbon Steel Blank Flanges undergoes:

1. Material Testing: XRF verification for grade compliance.

2. Dimensional Checks: CNC-machined to ±0.1mm precision.

3. Pressure Validation: Hydrostatic testing per ASME Section VIII.

4. Surface Inspection: Smooth finish (≤ Ra 3.2 μm) for optimal sealing.

Fast & Reliable Global Delivery

- Stock Orders: Shipped in 3–5 days.

- Custom Orders: Delivered in 2–4 weeks.

- Packaging: Wooden crates + anti-rust coatings for safe transit.

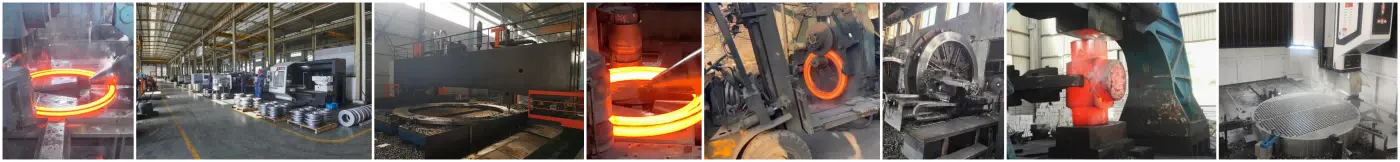

Quality Control

Factory Equipment

Shipping Packaging

FAQs

Q: Do your flanges meet API standards for sour gas environments?

A: Yes! We offer NACE MR0175-compliant options with anti-corrosion coatings.

Q: Can I order samples before bulk procurement?

A: Absolutely—samples are available for quality verification.

Q: What certifications do you provide?

A: ISO 9001, CE, API Q1, and ASME Section VIII. Material certificates (EN 10204 3.1) are included.

Q: How do you handle urgent MRO requests?

A: Our dedicated team prioritizes emergency orders with 72-hour turnaround options.

Contact Us

Need Carbon Steel Blank Flanges tailored to your project?

📧 Email: info@sxqinsteel.com

Serving Oil & Gas, Petrochemical, and Power Industries Since 2008

Learn about our latest products and discounts through SMS or email