- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

CS Blind Flanges

Xi 'An QinSteel Trading Co., Ltd | Leading Manufacturer & Global Supplier of High-Quality CS Blind Flanges

When you need leak-proof pipeline isolation that stands up to high-pressure demands, CS Blind Flanges deliver unmatched reliability. Engineered from carbon steel grades like ASTM A105 and A350 LF2, our flanges comply with API 6A, ASME B16.5, and EN 1092-1 standards, ensuring seamless integration into oil refineries, gas pipelines, and industrial systems. With sizes from ½" to 144" and pressure ratings up to Class 2500, we provide solutions for both standard and custom configurations—backed by ISO 9001-certified quality and rapid global shipping.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Why Our CS Blind Flanges Stand Out?

1. Global Compliance, Local Reliability

Every CS Blind Flange meets regional certifications like GOST (Russia) and INMETRO (Brazil), alongside international standards. Whether you’re sealing a refinery pipeline in the Middle East or a water treatment plant in Europe, our flanges are designed for universal acceptance.

2. Engineered for Extreme Conditions

With pressure ratings up to 138 MPa (API 6A) and corrosion-resistant coatings, our products thrive in sour gas environments and sub-zero temperatures.

3. Ready When You Are

30,000+ CS Blind Flanges are pre-made in common sizes (12"–24") for urgent orders. Bulk shipments arrive at global ports within 15 days.

4. Customization Without Compromise

Need non-standard dimensions or RTJ facings? Our R&D team delivers tailored solutions with full NDT reports and material traceability.

Applications: Where Performance Matters

- Oil & Gas: Isolate high-pressure pipelines in refineries and extraction sites.

- Power Generation: Secure boiler systems and turbine connections.

- Water Infrastructure: Seal large-diameter treatment pipelines (AWWA C207 compliant).

- Petrochemicals: Corrosion-resistant flanges for acidic chemical transport.

Quality Assurance: No Shortcuts

- Triple-Stage Inspections: Ultrasonic testing (UT), hydrostatic checks, and dimensional verification align with API Q1 protocols.

- Certified Materials: Mill test certificates (MTC) and NACE MR-0175 reports provided.

- Durable Packaging: Triple-layer moisture-proofing and wooden crates prevent transit damage.

Why Partner With Us?

- 15+ Years of Expertise: 200+ successful projects in oil & gas.

- Agile Logistics: Pre-cleared customs partnerships reduce delays.

- 24/7 Support: Engineers on standby to troubleshoot installation challenges.

Quality Control

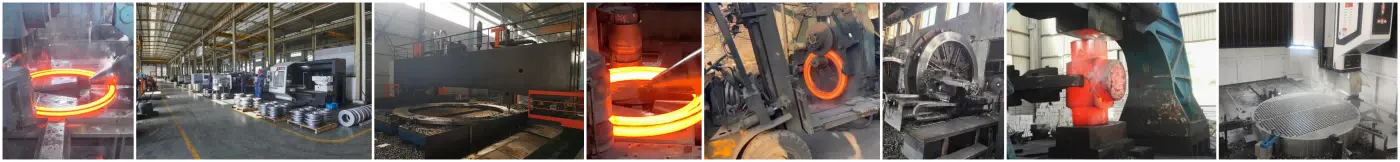

Factory Equipment

Shipping Packaging

FAQs: Your Concerns, Addressed

Are your products API-certified?

Yes—every batch meets API 6A/ASME B16.5 specs with full audit documentation.

Can I order customized sizes?

Absolutely. Share your technical drawings, and we’ll provide OEM/ODM solutions within 72 hours.

What's the lead time for 1,000 units?

Standard sizes ship in 7–15 days. Large diameters (24"+) require 3–4 weeks.

How do you ensure corrosion resistance?

Optional epoxy/PTFE coatings protect against harsh chemicals and humidity.

Do you offer bulk discounts?

Yes—contact us for tiered pricing on orders above 500 units.

Contact Us

Need a Quote or Samples?

Email info@sxqinsteel.com for pricing, CAD files, or expedited delivery options for CS Blind Flanges. Let's secure your pipelines—today.

Learn about our latest products and discounts through SMS or email