- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

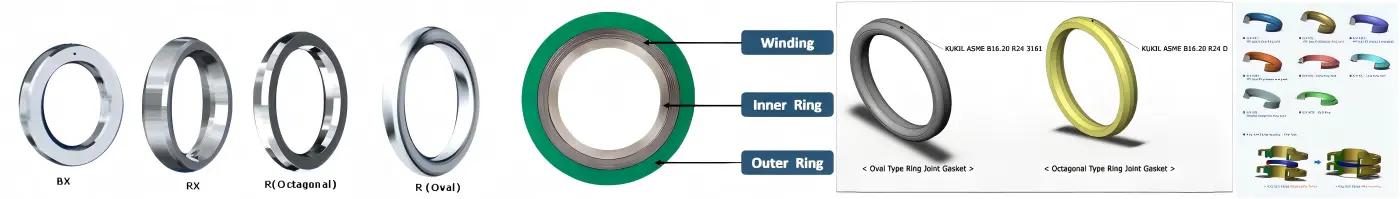

ASME B16.20 Gasket

ASME B16.20 Gaskets by Xi'an QinSteel Trading Co., Ltd

As a trusted manufacturer of ASME B16.20 gaskets, we specialize in high-performance sealing solutions for oil, gas, and petrochemical industries. With over XX years of expertise, our gaskets are engineered to meet strict international standards, ensuring leak-free performance in extreme temperatures (-200°C to +800°C) and pressures (up to Class 2500). Whether you need spiral-wound, ring joint, or custom-designed gaskets, our scalable production and global logistics guarantee timely delivery.

Product Description

The products are critical for maintaining flange integrity in high-pressure systems. Our products combine precision engineering with materials like stainless steel, carbon steel, and advanced fillers (graphite, PTFE) to deliver unmatched corrosion resistance and durability. Available in sizes from ½” to 60” (DN 15–1500), these gaskets are ideal for pipelines, refineries, and power plants.

Technical Specifications

| Parameter | Details |

|---|---|

| Standard | ASME B16.20 |

| Types | Spiral-Wound, R-Ring, RX-Ring, BX-Ring, Metal-Jacketed |

| Materials | Carbon Steel, Stainless Steel (304/316), Alloy 20 |

| Coatings | Zinc, PTFE, Chrome, Nickel, Plain |

| Pressure Rating | Class 150 to Class 2500 |

| Size Range | ½” to 60” (DN 15–DN 1500) |

| Certifications | ASME, ISO 9001, API 6A, PED, NACE MR-0175 |

Key Advantages

✅ ASME-Compliant Quality: Precision-machined to B16.20 specifications for reliable sealing.

✅ Wide Material Options: Choose from stainless steel, carbon steel, or specialty alloys for corrosive environments.

✅ Rapid Delivery: Ready-to-ship stock for urgent project needs.

✅ Customization: Tailor dimensions, coatings, and branding (OEM/ODM support).

✅ Global Certifications: Meets API, ISO, and PED requirements for seamless project approvals.

Applications

- Oil & Gas: High-pressure pipelines, wellheads, and offshore platforms.

- Refineries: Flange connections in cracking units and distillation columns.

- Chemical Plants: Corrosion-resistant sealing for aggressive media.

- Power Generation: Steam turbines and boiler systems.

Why Choose Us?

1. GMP-Certified Manufacturing

Our facilities use automated CNC machining and rigorous testing (helium leak tests, compression-resilience checks) to ensure zero-defect output.

2. Large Inventory, Fast Turnaround

Stock includes 10,000+ ASME B16.20 gaskets in common sizes, with lead times as short as 3–5 days.

3. End-to-End Support

From material traceability to shock-resistant packaging, we ensure compliance at every step.

4. Technical Expertise

Need a gasket for sour gas (NACE MR-0175) or extreme temperatures? Our R&D team delivers solutions.

Product Display

Factory Equipment

Shipping Packaging

FAQs

Q: Do your products comply with API 6A for oilfield applications?

A: Yes! Our ring joint gaskets meet API 6A standards for wellheads and blowout preventers.

Q: Can you customize coatings like PTFE or nickel?

A: Absolutely. We offer anti-corrosion coatings tailored to your operating environment.

Q: What’s the lead time for a 500-unit custom order?

A: Standard configurations ship in 3–5 days. Custom designs take 2–3 weeks.

Q: How do you prevent corrosion during shipping?

A: Gaskets are vacuum-sealed with desiccant packs and shipped in reinforced crates.

Q: Are samples available?

A: Yes—contact us to request samples for testing.

Contact Us

Email: info@sxqinsteel.com

Trusted by refineries, EPC contractors, and plant operators worldwide, our ASME B16.20 gaskets combine precision, durability, and compliance. Let’s secure your systems today!

Learn about our latest products and discounts through SMS or email