Modify 8.8 Grade High Tensile Bolt material grades (up to 12.9), coatings, or packaging – we’ve delivered customized bolts for offshore oil rigs and earthquake-resistant buildings.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

8.8 Grade High Tensile Bolt

Xi 'An QinSteel Trading Co., Ltd – Trusted 8.8 Grade High Tensile Bolt Manufacturer & Global Supplier

When you need reliable fasteners for heavy-load applications, 8.8 Grade High Tensile Bolts deliver unmatched performance. Engineered to withstand minimum tensile strengths of 800 MPa, these bolts are the backbone of structural integrity in construction, machinery, and infrastructure projects. At Xi 'An QinSteel, we combine precision manufacturing with global certifications to ensure every bolt meets rigorous safety and durability standards.

Technical Specifications

| Property | Details |

|---|---|

| Grade | 8.8 |

| Material | Medium Carbon Steel (ASTM A307, DIN 933) |

| Size Range | M6–M36 (Metric) / 5/16"–4" (Imperial) – Custom sizes available |

| Surface Treatment | Hot-Dip Galvanized, Zinc-Plated, Black Oxide, Phosphate, or Plain |

| Thread Type | Full or Partial Thread |

| Standards | ISO 898-1, DIN 934, ASME B18.2.1, ASTM F3125 |

Built to Last: Material Excellence

Our high-tensile bolts start with quenched and tempered medium carbon steel, achieving:

- Ultimate Tensile Strength: ≥800 MPa

- Yield Strength: ≥640 MPa

- Elongation: 12% minimum

- Hardness: 22–32 HRC

Choose from corrosion-resistant coatings like hot-dip galvanizing (up to 85 µm thickness) for coastal projects or zinc plating for industrial machinery.

Why Our 8.8 Grade Bolts Outperform?

✅ Structural Reliability

Withstand extreme vibration and dynamic loads in bridges, towers, and heavy equipment.

✅ Global Compliance

Precisely machined threads meet ISO/DIN/ASTM specifications for seamless international project approvals.

✅ Environment-Ready

Select coatings protect against saltwater, humidity, and chemical exposure.

✅ Custom Fit

Need non-standard lengths or alloy blends? Our OEM team can prototype within 7 days.

Where They Excel: Key Applications?

- Steel Construction: Beam connections, truss assemblies

- Renewable Energy: Wind turbine bases, solar mounting systems

- Transportation: Truck chassis, rail track components

- Industrial Machinery: Presses, conveyor systems, hydraulic equipment

Why Global Buyers Choose Xi 'An QinSteel?

🚚 Never Miss a Deadline

With 15,000+ metric tons of Grade 8.8 bolts in stock, we ship 85% of orders within 48 hours – even for 500,000-unit contracts.

🔍 Certifications You Can Trust

Every batch includes test certificates for:

- ISO 9001 / CE Marking

- ASTM F3125 (A325 Equivalent)

- EN 14399 (Europe) / JIS B1186 (Asia)

🛠️ Your Vision, Our Execution

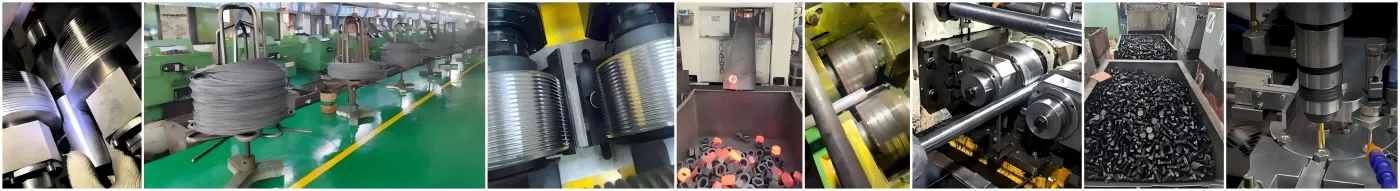

⚙️ Precision at Scale

Automated CNC machining ensures ±0.1 mm dimensional accuracy across 10,000-unit batches.

Quality Assurance Protocol

1. Raw Material Testing: Spectrometer verification of steel alloys

2. Production Monitoring: Real-time torque and hardness checks

3. Final Inspection: Salt spray testing (500+ hours), tensile load validation

Secure Global Shipping

- Packaging: Waterproof wooden crates or steel-strapped cartons

- Delivery: 15-day average transit to EU/US ports via DDP incoterms

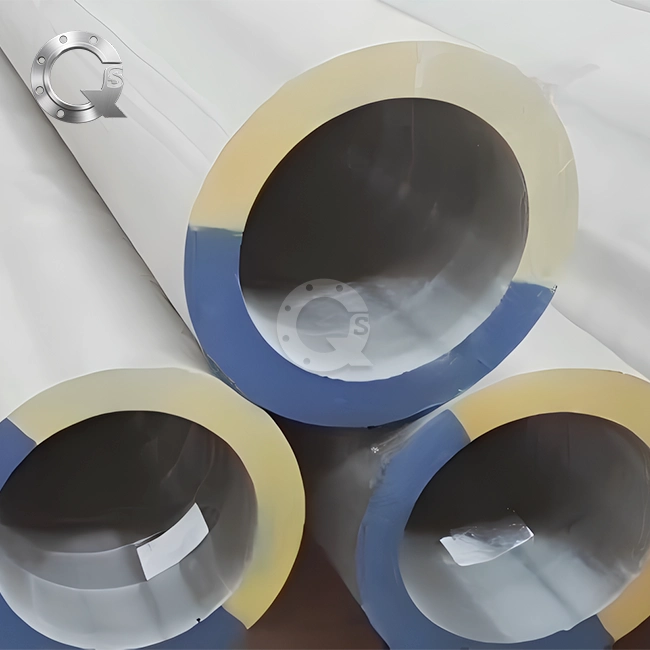

Quality Control

Factory Equipment

Shipping Packaging

FAQ

Can I get samples before bulk ordering?

Yes – request free samples (you cover shipping) to test fit and coating quality.

What’s the MOQ for customized bolts?

MOQ starts at 5,000 units for standard specs; 20,000 units for custom coatings/sizes.

How do you prevent bolt corrosion during shipping?

VCI anti-rust paper + desiccant packs inside sealed polyethylene bags.

Do you assist with load capacity calculations?

Our engineers provide free technical support for bolt selection based on your project’s stress requirements.

Contact Us

📧 Email: info@sxqinsteel.com

Attach your 8.8 Grade High Tensile Bolt specifications or sketch – we’ll respond with a quote in 4 working hours.

Learn about our latest products and discounts through SMS or email