- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Threaded Flange ASME B16.5

Xi 'An QinSteel Trading Co., Ltd | Threaded Flange ASME B16.5 Manufacturer & Global Supplier

When securing high-pressure pipeline connections, Threaded Flange ASME B16.5 components are the go-to solution for industries demanding precision and reliability. At Xi 'An QinSteel Trading Co., Ltd, we engineer these flanges to meet rigorous ASME B16.5 standards, ensuring leak-proof performance in oil, gas, and petrochemical systems. Our threaded design eliminates welding needs, simplifying installation in hazardous or hard-to-access environments. With pressure classes from 150 to 2500 and sizes spanning ½" to 24", our flanges adapt seamlessly to global piping networks.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Materials: ASTM A105 (Carbon Steel), A350 LF2 (Low-Temp), A182 F304/F316 (Stainless), Duplex Steels (F51/F53/F55).

Why Our ASME B16.5 Threaded Flanges Stand Out?

✅ Certified Precision: Every Threaded Flange ASME B16.5 undergoes strict dimensional checks and hydrostatic testing to guarantee compliance.

✅ Material Versatility: Choose from carbon steel for cost efficiency or duplex grades for corrosive, high-temperature environments.

✅ Rapid Deployment: Our in-house stock of 500,000+ units enables delivery within 7–10 days for urgent orders.

✅ Global Compliance: Pre-certified with ISO 9001, PED, API 6A, and NACE MR0175 for worldwide acceptance.

Applications

- Oil & gas pipelines and refinery equipment

- Chemical processing plants

- Water treatment systems and power generation

- High-pressure industrial networks

Built for Your Challenges

1. Eliminate Supply Delays

With ready stock and agile logistics, we cut lead times to ≤4 weeks for bulk orders.

2. Combat Corrosion & Leaks

Opt for stainless steel or duplex materials with NACE compliance for sour service environments.

3. Customize with Confidence

Our R&D team tailors threading profiles, sizes, and coatings to your specs. Request samples to verify fit and quality.

4. Certification Transparency

Each flange ships with material traceability (MTC) and test reports (NDE, pressure testing).

Quality Assurance

- Dimensional Accuracy: Laser-scanned threading and surface finish checks.

- Pressure Testing: Validated up to 1.5x rated pressure.

- Packaging: Wooden crates with moisture-resistant wrapping for safe global transit.

Quality Control

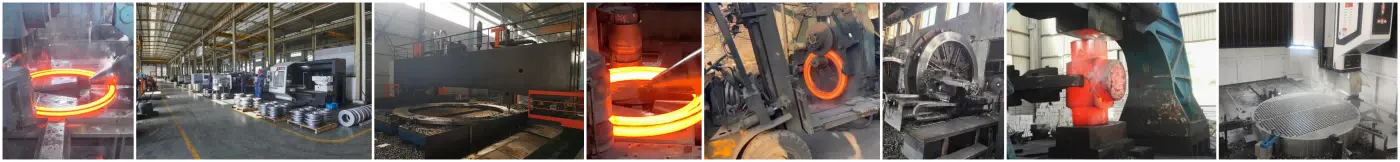

Factory Equipment

Shipping Packaging

FAQ

Q: Can you customize flanges beyond ASME B16.5 dimensions?

A: Yes! Our OEM services accommodate non-standard sizes, materials, or threading.

Q: What certifications do your products hold?

A: All flanges comply with ASME B16.5, ISO 9001, and PED/CE. Regional certs (GOST, CRN) available on request.

Q: How do you ensure leak-proof connections?

A: Precision-machined threads paired with RF/FF facings create airtight seals with mating flanges.

Q: Do you support small-volume orders?

A: Absolutely. We serve both bulk procurement and urgent spot purchases.

Contact Us

Email: info@sxqinsteel.com

Samples Available: Test our Threaded Flange ASME B16.5 in your system risk-free.

Trusted by oil giants and chemical plants worldwide, we deliver reliability threaded into every flange.

Learn about our latest products and discounts through SMS or email