A106 Gr.B carbon steel seamless pipes work well for many industrial applications, especially when the environment is non-corrosive and the temperature is normal (≤350℃). These lines are great for moving fluids for business at low to medium pressure. A106 Gr.B carbon steel is a great choice for your pipeline job because it is very strong, handy in lots of situations, and cheap. If a project needs a lot of strength, good weldability, and resistance to moderate temperature and pressure, this type of steel is a great choice. Knowing when to use A106 Gr.B carbon steel for seamless pipes can have a big impact on how well your pipeline systems work, how safe they are, and how long they last.

Understanding A106 Gr.B Carbon Steel Seamless Pipes

Composition and Properties of A106 Gr.B Carbon Steel

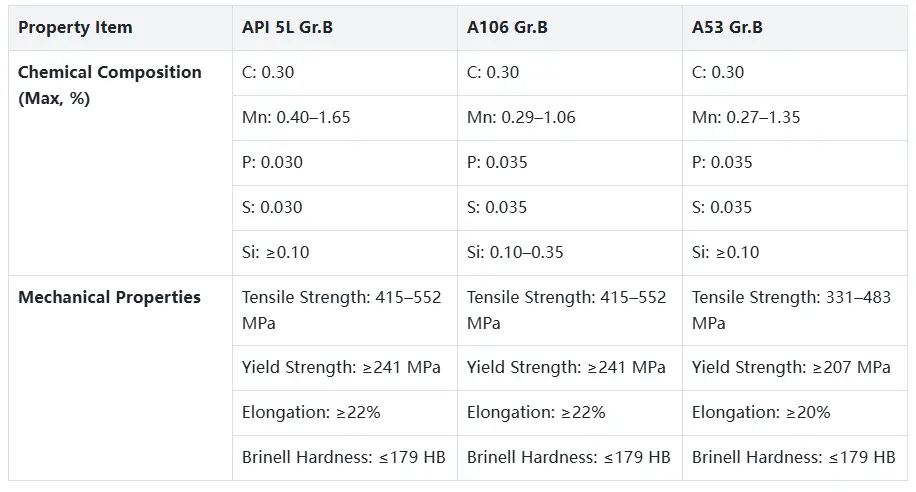

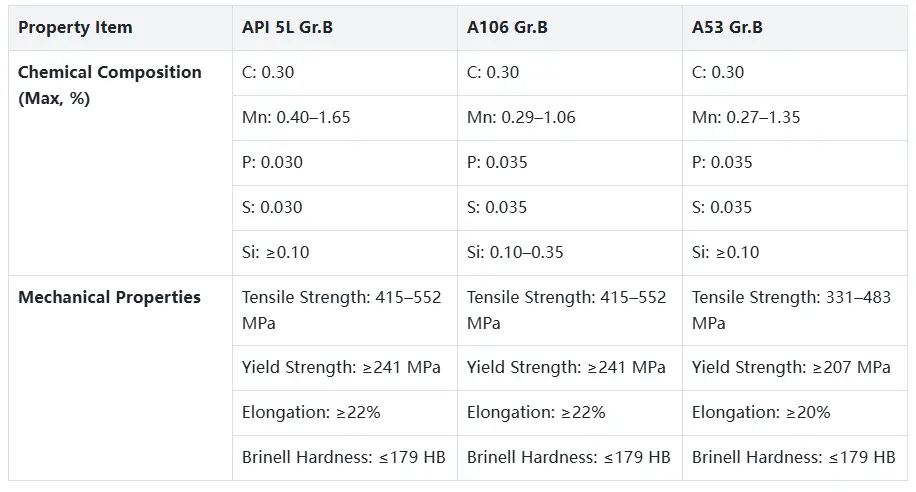

A106 Gr.B is a medium-carbon steel that is well-balanced. It normally has carbon (0.30%), manganese (0.29–1.06%), and a few other things, like phosphorus, sulfur, and silicon. This substance gives A106 Gr. B its unique properties:

- Tensile strength of 60,000 psi or more

- Ductility that is high

- Is very easy to weld

- Some resistance to low-level heat

A106 Gr.B carbon steel seamless pipes can be used in a lot of different settings because they are strong and reliable.

Manufacturing Process of A106 Gr.B Seamless Pipes

Because of how they are made, A106 Gr.B seamless pipes are high-quality and high-performing. These pipes are made without welding in the hot-forming process. This evens out the shape of the entire pipe wall. The process normally has:

- Heating steel billets to a very high temperature

- Creating a hollow shell by poking holes in the hot metal bars

- Rolling the shell and then pulling it to get the right width and thickness for the wall

- Heating method to change the way the material acts when it's used mechanically

- Quality control and tests

Welded pipes have weak spots because of joints, but this design doesn't have any, so the pipes are stronger and more reliable.

Advantages of A106 Gr.B Carbon Steel Seamless Pipes

A106 Gr.B carbon steel seamless pipes are a good choice for many industrial applications since they have several perks, including:

- Uniform strength: The pipe doesn't have any joints, so it is the same strength all the way through.

- Pressure resistance: These pipes can take more pressure from the inside and outside than pipes that are soldered together of the same grade.

- Temperature tolerance: safe to use up to 350℃ (662°F).

- Corrosion resistance: A106 Gr.B is not as good as stainless steel at fighting corrosion, but it does a decent job of resisting air corrosion.

- Cost-effectiveness: This steel usually costs less than higher-alloy steels and gives you a good balance of performance and price.

- Due to these benefits, A106 Gr.B carbon steel seamless pipes are a helpful and trustworthy choice for many types of industrial piping systems.

Applications and Industries for A106 Gr.B Carbon Steel Seamless Pipes

Oil and Gas Industry Applications

In the oil and gas business, A106 Gr.B carbon steel seamless pipes are very important for a lot of different things:

- Moving natural gas and crude oil

- Pipelines used in oil refining

- Pipelines for bases in deep water

- Well pipes and covers

These lines are great for oil and gas activities because they can handle a lot of pressure and weight. They can deal with the high pressures of deep well digging and the harmful effects of crude oil and natural gas.

Power Generation and Industrial Applications

Power is often made with the help of businesses that use A106 Gr.B carbon steel seamless pipes:

- Power companies' lines for steam

- Tubes used in boilers

- Tools for moving heat

- Chemical structures

- Petroleum plants for chemicals

These pipes can handle high temperatures and are strong, so they are a good choice for light heat and pressure. They are often used in power companies for steam lines where safety and reliability are very important. They are a good option for chemical processes because they don't break down when they come in contact with many different chemicals.

Water and Waste Management Systems

A106 Gr.B carbon steel seamless pipes are also used to control water and trash:

- City water lines for service

- Water-cleaning factories

- Sewage treatment plants

- Ways to water

These lines are good for systems that move and clean water because they don't rust and are strong enough to last a long time. They can take the stress of water delivery systems, and the good and bad effects of water on pipes don't hurt them.

Factors to Consider When Choosing A106 Gr.B Carbon Steel Seamless Pipes

Temperature and Pressure Requirements

Think carefully about the temperature and pressure of your application before using A106 Gr.B carbon steel seamless pipes:

- Temperature range: A106 Gr.B is good at temperatures as high as 350℃ (662°F). You may need to use different materials if it gets hotter.

- Pressure: These pipes can handle moderate to high pressures, but the exact limits depend on the size of the pipe and what the purpose needs.

- Fluctuations: Consider if the system will have a lot of temperature or pressure changes. This can affect the long-term performance of the material.

For as long as it is in use, the right pipe must be able to safely and efficiently handle the predicted conditions. This is very important to keep in mind.

Corrosion Resistance and Environmental Factors

A106 Grade B While carbon steel generally resists rusting in the atmosphere well, you should consider the specific conditions of the area where it will be used.

- Makeup of the fluid: Think about how much the fluids that are being moved can break down other things. Things that are very acidic may not go well with A106 Gr.B.

- The surroundings outside: Look at things like humidity, salinity, and exposure to harmful chemicals in the world around you.

- Protective steps: Find out if your object needs more protection from corrosion, like coatings or cathodic protection.

In places where rusting could happen, the equipment's long-term safety and functionality might need to be ensured by using different materials or extra protective steps.

Cost-Effectiveness and Long-Term Performance

When considering A106 Gr.B carbon steel seamless pipes, take the short-term and long-term prices into account:

- Initial Cost: Compare the price of A106 Gr.B pipes with other items that can be used in your project.

- Upkeep Costs: Consider the cost of maintenance and potential substitutes over the system's lifetime.

- Longevity: Find out how long A106 Gr.B pipes will last in your case and compare that to other choices.

- Efficiency: Consider how the material properties of A106 Gr.B might affect how well the system works and how much it costs to operate.

A106 Gr.B carbon steel seamless pipes are generally a good deal, but there should be a full cost-benefit analysis of the whole job.

Conclusion

A106 Gr.B carbon steel seamless pipes are a useful and reliable choice for many industrial applications, particularly those that work with low temperatures and pressures. They are great for oil and gas, power generation, and water control because they are cheap, strong, and long-lasting. Think about how much resistance to corrosion, high temperatures, high pressure, and long-term success you need if you plan to use A106 Gr.B for your job. Putting the right pipes in the right places will make sure your plumbing works well and safely and doesn't cost too much.

FAQs

What is the maximum temperature that can be safely used with A106 Gr.B carbon steel seamless pipes without harming them?

Temperatures of up to 350°C (662°F) are no problem for A106 Gr. B carbon steel seamless pipe.

Is it safe to use A106 Gr.B lines in areas where strong chemicals could hurt them?

They do well in atmospheric rust, but may not be good in highly corrosive materials unless they are somehow protected.

How do A106 Grade B seamless pipes compare to welding pipes?

A106 Gr.B seamless pipes tend to be stronger and better at resisting pressure than soldered pipes of the same grade because they have an even build.

Need High-Quality A106 Gr.B Carbon Steel Seamless Pipes? | QinSteel

QinSteel is one of the best companies for making and selling A106 Gr.B carbon steel seamless pipes. We meet international standards and make sure our high-quality, precision-engineered things are always on time. We've been doing this for 20 years. Our many different goods are designed to last and are used in a lot of different fields. Emailing info@sxqinsteel.com can help you get good advice on which pipes to use, make sure they are brought on time, and get a good deal.

References

American Society for Testing and Materials (ASTM). "ASTM A106/A106M Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service." ASTM International, 2019.

Smith, J.R. "Carbon Steel Piping Materials for High-Temperature Applications in the Oil and Gas Industry." Journal of Petroleum Technology, vol. 72, no. 5, 2020, pp. 45-52.

Johnson, L.M. and Thompson, R.K. "Comparative Analysis of Seamless vs. Welded Pipes in Industrial Applications." Materials Science and Engineering: A, vol. 715, 2018, pp. 1-10.

International Association of Oil & Gas Producers (IOGP). "Material Selection for Oil and Gas Pipeline Systems." IOGP Report 497, 2018.

Chen, X. and Wang, Y. "Corrosion Behavior of Carbon Steel Pipes in Various Industrial Environments." Corrosion Science, vol. 138, 2018, pp. 8-21.

American Petroleum Institute (API). "API 5L Specification for Line Pipe." 46th Edition, API Publishing Services, 2018.