Understanding ASME B16.9 Reducers and Erosion

What are ASME B16.9 Reducers?

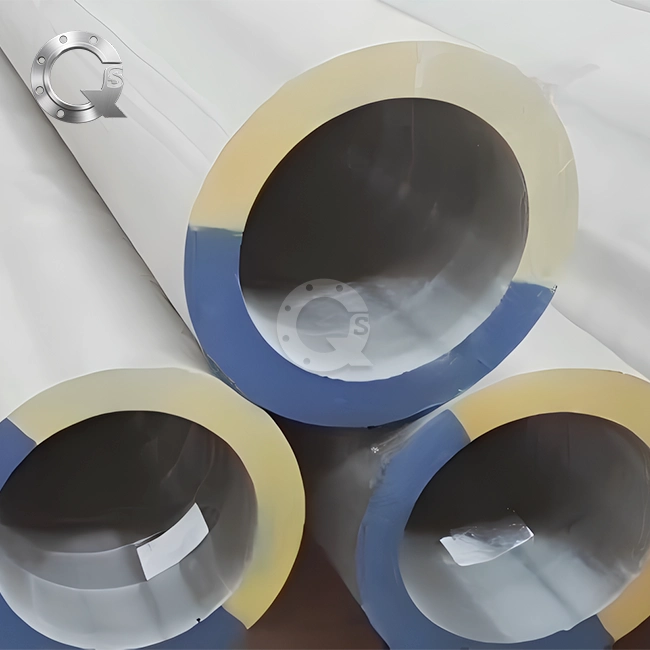

ASME B16.9 reducers are essential components in piping systems, designed to connect pipes of different diameters smoothly. These fittings are manufactured according to the stringent standards set by the American Society of Mechanical Engineers (ASME), ensuring high quality and reliability. ASME B16.9 reducers are commonly used in various industries, including oil and gas, chemical processing, and water treatment plants.

Common Causes of Erosion in ASME B16.9 Reducers

Erosion in ASME B16.9 reducers can occur due to several factors. High-velocity fluid flow, especially when carrying abrasive particles, can gradually wear away the inner surface of the reducer. Corrosive chemicals in the fluid can also accelerate erosion. Additionally, turbulence created by sudden changes in flow direction or velocity can lead to localized erosion hotspots. Understanding these causes is crucial for implementing effective preventive measures.

Signs of Erosion in ASME B16.9 Reducers

Identifying erosion in ASME B16.9 reducers early is key to preventing catastrophic failures. Some common signs include visible thinning of the reducer walls, pitting on the inner surface, and changes in the reducer's shape or dimensions. In severe cases, you may notice leaks or hear unusual sounds during operation. Regular inspections using non-destructive testing methods can help detect erosion before it becomes critical.

Steps to Address Erosion in ASME B16.9 Reducers

Conducting a Thorough Inspection

When erosion is suspected in ASME B16.9 reducers, a comprehensive inspection is the first crucial step. Begin with a visual examination to identify any obvious signs of wear or damage. Follow this with more advanced non-destructive testing techniques such as ultrasonic thickness measurement or radiographic inspection. These methods provide accurate data on the remaining wall thickness and help pinpoint areas of concern. Document all findings meticulously, as this information will be vital for decision-making and future reference.

Measuring Remaining Wall Thickness

Accurate measurement of the remaining wall thickness is essential in determining the severity of erosion in ASME B16.9 reducers. Utilize precision instruments like ultrasonic thickness gauges for this purpose. Take measurements at multiple points along the reducer, paying special attention to areas prone to higher wear, such as the transition zones. Compare these measurements with the original specifications and the minimum allowable thickness as per ASME B16.9 standards. This comparison will help you assess whether the reducer can continue in service or requires immediate replacement.

Determining When to Replace the Reducer

The decision to replace an ASME B16.9 reducer should be based on a careful evaluation of the inspection results. If the wall thickness at any point falls below the minimum allowable thickness specified in ASME B16.9, immediate replacement is necessary to prevent potential failures. Even if the thickness is above the minimum, consider replacement if the erosion rate is high or if the remaining service life is short. Factor in the criticality of the system, potential downtime costs, and safety risks when making this decision. It's always better to err on the side of caution when it comes to maintaining the integrity of your piping system.

Preventive Measures and Long-term Solutions

Implementing Erosion Control Strategies

To mitigate erosion in ASME B16.9 reducers, implementing effective control strategies is crucial. One approach is to modify the fluid flow characteristics. This can be achieved by adjusting the flow rate or introducing flow straighteners to reduce turbulence. Another strategy involves using more erosion-resistant materials for the reducers, such as high-chromium alloys or ceramics, in particularly harsh environments. Coating the inner surface of the reducer with protective materials like epoxy or ceramic compounds can also significantly enhance its erosion resistance.

Regular Maintenance and Inspection Schedules

Establishing a robust maintenance and inspection schedule is key to preventing severe erosion issues in ASME B16.9 reducers. Develop a comprehensive plan that includes regular visual inspections, periodic thickness measurements, and detailed documentation of findings. The frequency of these inspections should be based on factors such as the aggressiveness of the fluid, operating conditions, and historical data on erosion rates. Implement predictive maintenance techniques, such as trend analysis of thickness measurements, to anticipate when replacements might be needed before critical thresholds are reached.

Upgrading System Design for Enhanced Durability

For a long-term solution to erosion problems in ASME B16.9 reducers, consider upgrading the overall system design. This might involve re-evaluating the piping layout to minimize areas of high turbulence or velocity. Incorporating additional reducers or using gradual transitions can help distribute wear more evenly. In some cases, switching to alternative fitting types or custom-designed components may provide better erosion resistance. Consult with engineering experts to analyze your specific system requirements and develop an optimized design that balances performance, durability, and cost-effectiveness.

Conclusion

Addressing erosion in ASME B16.9 reducers requires a proactive and systematic approach. By conducting regular inspections, accurately measuring wall thickness, and replacing components when necessary, you can maintain the integrity and safety of your piping system. Implementing preventive measures and considering long-term solutions will help extend the lifespan of your reducers and improve overall system reliability. Remember, timely action and continuous monitoring are key to preventing costly failures and ensuring the efficient operation of your industrial processes.

FAQs

How often should ASME B16.9 reducers be inspected for erosion?

The inspection frequency depends on the operating conditions, but generally, a visual inspection every 6-12 months and a thorough thickness measurement annually is recommended.

Can eroded ASME B16.9 reducers be repaired instead of replaced?

In most cases, it's safer and more cost-effective to replace eroded reducers rather than attempt repairs, especially if the erosion is significant.

What materials are most resistant to erosion for ASME B16.9 reducers?

High-chromium stainless steels, duplex stainless steels, and some nickel-based alloys offer excellent erosion resistance for ASME B16.9 reducers.

Expert ASME B16.9 Reducer Solutions for Erosion Prevention | QinSteel

At QinSteel, we specialize in providing high-quality ASME B16.9 reducers engineered to withstand harsh industrial environments. Our expert team can help you select the right materials and designs to minimize erosion risks in your piping systems. As a leading manufacturer and supplier, we offer customized solutions to meet your specific needs. Contact us at info@sxqinsteel.com to discuss how we can enhance the durability and performance of your industrial piping systems.

References

ASME B16.9-2018: Factory-Made Wrought Buttwelding Fittings. American Society of Mechanical Engineers.

Erosion in Piping Systems: Mechanisms, Detection, and Prevention. Journal of Pipeline Engineering, Vol. 15, No. 3.

Materials Selection for Erosion Resistance in Process Equipment. Corrosion Engineering, Science and Technology, Vol. 52, Issue 4.

Non-Destructive Testing Techniques for Piping System Integrity Assessment. NDT & E International, Vol. 76.

Predictive Maintenance Strategies for Industrial Piping Systems. Reliability Engineering & System Safety, Vol. 180.

Flow-Induced Corrosion and Erosion in Piping Systems: A Review. Wear, Vol. 376-377, Part A.