- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

AS 2129 Flanges

AS 2129 Flanges Manufacturer | Precision-Crafted for Global Industrial Projects

At Xi’an QinSteel Trading Co., Ltd, we specialize in manufacturing AS 2129 Flanges designed to meet the rigorous demands of industrial piping systems. With a focus on precision engineering and compliance, our flanges are trusted by project managers and procurement teams across Australia, Southeast Asia, and beyond.

Why AS 2129 Flanges?

The products are engineered for high-pressure applications in oil & gas, water infrastructure, and chemical processing. Compliant with Australian standards, these flanges ensure leak-proof performance, even in extreme environments. Whether you’re retrofitting existing systems or building new pipelines, our products offer:

- Full Compliance: Meets AS 2129 Tables A–T for pressure ratings up to 26,000 kPa.

- Material Versatility: Carbon steel, stainless steel (F304/F316), and duplex options.

- Size Flexibility: From DN15 for residential plumbing to DN1800 for industrial networks.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Built to Last: Materials & Customization

Our AS 2129-compliant flanges are crafted from corrosion-resistant materials like A350 LF2 (low-temperature steel) and duplex stainless steel (F51/F53), ideal for coastal or chemical-heavy environments. Need a custom solution? We offer:

- OEM/ODM Services: Tailor dimensions, drilling patterns, or surface treatments.

- Rapid Prototyping: Submit your drawings for samples within 10 business days.

Where Our AS 2129 Flanges Excel?

1. Water Treatment Plants: Galvanized flanges resist corrosion in pipelines.

2. Oil & Gas Systems: High-yield carbon steel handles pressure fluctuations.

3. Chemical Processing: PTFE-lined options prevent chemical buildup.

Why Partner With Us?

- GMP-Certified Production: Rigorous quality checks at every stage.

- 48-Hour Quotation: Get pricing and lead times fast, even for bulk orders.

- Global Logistics: Warehouses in Australia and SEA ensure on-time delivery.

- Traceability: QR-coded flanges with instant access to MTCs and test reports.

Quality Assurance You Can Trust

Every flange undergoes:

1. Dimensional Checks: Laser scanning for perfect fitment.

2. Pressure Testing: Validated to AS 2129 standards.

3. Material Verification: Third-party lab testing available.

Secure Packaging & Fast Shipping

We use shock-resistant pallets with waterproof wrapping to protect your AS 2129 Flanges during transit. Options include:

- Air Freight: 3–7 days for urgent orders.

- Sea Freight: Cost-effective for bulk shipments.

Quality Control

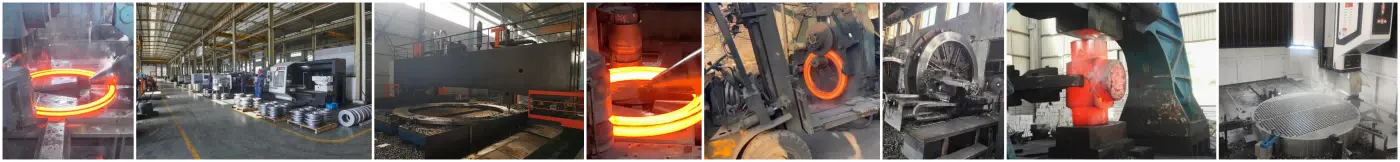

Factory Equipment

Shipping Packaging

FAQs

Q: Can you supply flanges for offshore platforms?

A: Yes! Our duplex steel flanges meet NACE MR0175 for saltwater environments.

Q: Do you offer galvanized products?

A: Absolutely—hot-dip galvanizing adds extra corrosion protection.

Q: What certifications do you provide?

A: ISO 9001, AS/NZS 3678, and material test reports (EN 10204 3.1).

Q: How quickly can you deliver 1,000 units?

A: From stock—5 business days. Custom orders take 15–25 days.

Q: What if I need a non-standard size?

A: Share your specs, and we’ll craft a solution.

Contact Us

Email: info@sxqinsteel.com

With ready-to-ship inventory and expertise in AS 2129 Flanges, we're your partner for compliant, durable piping solutions. Let's build something reliable together!

Learn about our latest products and discounts through SMS or email