- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

SABS 1123 Table 1000/3 Flanges

SABS 1123 Table 1000/3 Flanges: Precision Engineered for High-Pressure Systems

When sourcing reliable pipeline components for critical infrastructure projects, SABS 1123 Table 1000/3 Flanges stand out as the gold standard in durability and compliance. Designed to meet South Africa’s stringent SANS 1123 specifications, these flanges ensure seamless performance in oil, gas, and water systems under extreme pressure (250–4000 kPa). At Xi’an QinSteel, we combine rigorous certification adherence with global manufacturing excellence to deliver flanges that keep your projects on schedule and within budget.

Product Overview

The products are engineered for high-pressure industrial piping systems requiring uncompromising reliability. Available in welding neck (WN), slip-on (SO), plate, and screwed types, they support sizes from DN10 to DN3600, making them ideal for small instrumentation lines or large-scale pipeline networks.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Why Our Flanges Excel in Demanding Environments?

1. SABS 1123 Compliance Guaranteed

Every flange undergoes precision machining to meet Table 1000/3 dimensional and pressure tolerances, validated through hydrostatic testing and material traceability reports.

2. Material Versatility

Choose from carbon steel for cost-sensitive projects, stainless steel for corrosion resistance, or duplex alloys for acidic environments.

3. Rapid Bulk Order Fulfillment

With 10,000+ pre-stocked SABS 1123 Table 1000/3 Flanges units and strategic African warehouses, we ship bulk orders within 7 days—even for custom coatings or ANSI-compatible bolt patterns.

4. Dual Certification Efficiency

Our flanges simultaneously comply with SABS 1123 and global standards (API, ASME), reducing approval delays by 30% for cross-regional projects.

Applications

- Oil & Gas: High-temperature wellhead systems, refinery pipelines.

- Water Treatment: Coastal desalination plants, wastewater management.

- Infrastructure: Mining slurry transport, power generation cooling systems.

Trusted by Procurement Teams Across Three Continents

Africa-Focused Solutions

- Certifications: NRCS-approved, SABS 1123 compliance.

- Logistics: 72-hour delivery across Southern/East Africa via Durban/Nairobi hubs.

Middle East Performance

- Durability: API 6A-certified flanges for 138 MPa offshore drilling.

- Customization: Non-standard bore sizes for legacy pipeline upgrades.

Southeast Asia Adaptability

- Corrosion Resistance: PTFE-coated variants for humid, saline environments.

Quality Control

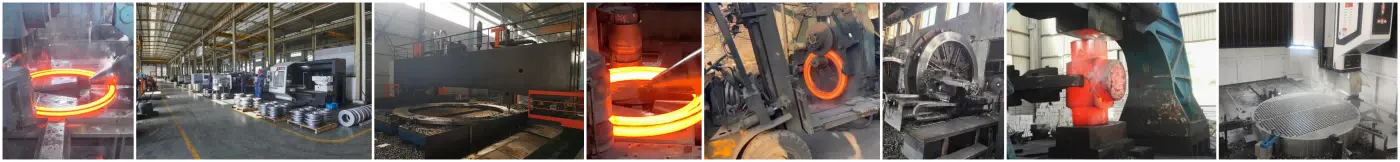

Factory Equipment

Shipping Packaging

FAQs: Addressing Your Critical Concerns

Can you customize flanges beyond standard SABS 1123 specs?

Yes! Our R&D team adapts dimensions, materials, and coatings to your project’s technical needs.

Do you provide pressure-testing certifications?

Every shipment includes material test reports (MTRs) and hydrostatic test certificates.

How do you ensure damage-free delivery to remote sites?

Flanges are packed in anti-corrosion-treated wooden crates with GPS-tracked logistics.

What’s the MOQ for custom orders?

No strict MOQ—we offer volume discounts for 5,000+ units.

Contact Us

Email info@sxqinsteel.com for:

- Instant pricing for bulk orders.

- Technical datasheets with SABS 1123 compliance details.

- Custom project consultations within 24 hours.

Let's engineer SABS 1123 Table 1000/3 Flanges reliability into your next pipeline project—without the delays.

Learn about our latest products and discounts through SMS or email