- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

A335 P5 Pipe

Engineered for Extreme Conditions: A335 P5 Pipe Solutions

When you need reliable piping for high-temperature environments, A335 P5 Pipe delivers unmatched performance. Designed for refinery systems, power plants, and petrochemical applications, these chromium-molybdenum alloy pipes withstand temperatures up to 580°C (1,076°F) while maintaining structural integrity. As an ASME-certified manufacturer, we ensure every pipe meets stringent ASTM A335 standards, giving you confidence in critical operations.

Key Specifications

| Parameter | Specification |

|---|---|

| Standard | ASTM A335, ASME SA335 |

| Grade | P5 (4-6% Cr, 0.45-0.65% Mo) |

| Size Range | 1/2" to 24" OD |

| Thickness | SCH40, SCH80, Custom Schedules |

| Pressure | Up to 2,500 PSI |

| Temperature | -29°C to 580°C |

Why A335 P5 Pipe Outperforms Carbon Steel?

1. High-Temperature Resilience

Optimized chromium-molybdenum composition resists oxidation and creep in furnace tubes and steam lines.

2. Seamless Reliability

Precision manufacturing eliminates weak points, ideal for high-pressure refinery applications.

3. Global Compliance

Pre-certified for ASTM, NACE MR0175, and PED standards—no delays during project audits.

4. Ready-to-Ship Inventory

Sch40/Sch80 pipes available in standard sizes for urgent turnaround.

Critical Applications

- 🔥 Refinery furnace tubes

- ⚡ Power plant boiler systems

- 🛢️ Petrochemical cracking units

- 🌊 Offshore oil/gas processing

Material Properties

Chemical Composition

| Element | Cr | Mo | C |

|---|---|---|---|

| % Range | 4.0-6.0 | 0.45-0.65 | ≤0.15 |

Mechanical Performance

| Tensile Strength | Yield Strength | Hardness |

|---|---|---|

| 415-585 MPa | ≥205 MPa | ≤250 HB |

Why Partner With Us?

✅ 25+ Years of Expertise

Specializing in alloy pipes for Shell, ExxonMobil, and other Fortune 500 projects.

✅ Zero-Defect Guarantee

Every A335 P5 Pipe undergoes UT, PMI, and hydrostatic testing.

✅ Fast-Track Logistics

Shipments reach Middle East oilfields in 7 days, Asia-Pacific refineries in 10.

✅ Custom Solutions

Provide your specs—we handle beveling, coatings, or non-standard lengths.

Quality Control

Factory Equipment

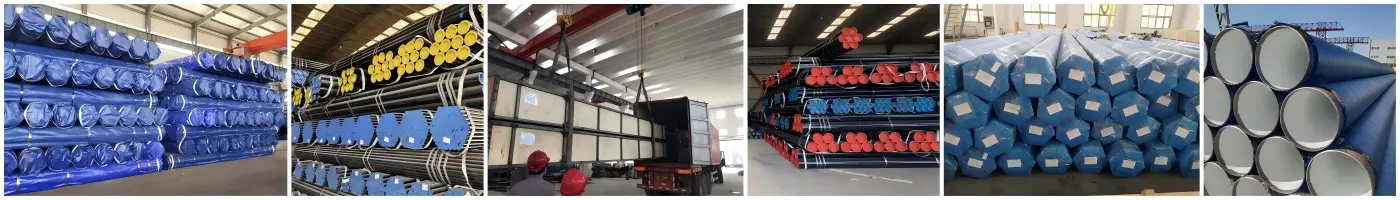

Shipping Packaging

FAQs

Q: Can you expedite orders for refinery shutdowns?

A: Yes! Our 50,000-ton stockpile ensures 72-hour dispatch for Sch40/Sch80 pipes.

Q: Are your pipes compliant with sour gas standards?

A: We offer NACE MR0175-certified options for hydrogen sulfide environments.

Q: Do you provide post-weld heat treatment?

A: Yes—consult our engineers for PWHT protocols matching your project needs.

Q: What packaging prevents corrosion during shipping?

A: Triple-layer VCI film + wooden crates ensure damage-free delivery.

Contact Us

📧 Email: info@sxqinsteel.com

Response within 90 minutes during business hours.

Optimize your high-temperature systems with ASTM-certified A335 P5 Pipe—contact us today for competitive pricing and sample requests.

Learn about our latest products and discounts through SMS or email