- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

WN Orifice Flanges

WN Orifice Flanges Manufacturer | Precision Flow Measurement Solutions

WN Orifice Flanges are critical components for accurate flow measurement in high-pressure oil, gas, and chemical pipelines. At Xi 'An QinSteel Trading Co., Ltd, we engineer these flanges to meet ASME B16.36 and API 6A standards, ensuring leak-proof performance even in extreme conditions. With over [X] years of expertise, we deliver precision-machined solutions that balance durability with cost-efficiency for global projects.

What Are WN Orifice Flanges?

These welding neck flanges feature integrated orifice plate holders and pressure tap openings, enabling precise flow rate calculations. Unlike standard flanges, the products have tapered hubs to reduce stress concentrations and ensure seamless integration into pipelines handling up to 2,500 psi.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Why Our WN Orifice Flanges Outperform Competitors?

1. Zero-Compromise Precision

Our CNC-machined flanges achieve ±0.01mm bore tolerances, critical for maintaining ISO 5167-2 compliance in custody transfer applications.

2. Material Versatility

Choose from carbon steel, low-temperature alloys, or corrosion-resistant duplex steels (F51/F55) for sour gas or subsea environments.

3. Rapid Customization

Need non-standard bolt patterns or NACE MR0175-compliant finishes? Our OEM team delivers prototypes in 7–10 working days.

4. Inventory-Driven Speed

30% of our WN Orifice Flanges are kept in Houston/Rotterdam/Singapore warehouses for 48-hour regional dispatch.

Applications Trusted by Industry Leaders

- Oil & Gas: Custody transfer metering skids

- Chemicals: Corrosive media flow control

- Power Plants: High-temperature steam lines

Quality Assurance Protocol

1. PMI Testing: Verify material chemistry via XRF guns

2. CMM Inspection: 3D profile validation of orifice bores

3. Hydrostatic Testing: 1.5x rated pressure for 10 minutes

Why 85% of Clients Reorder With Us?

- GMP-Certified Workshops: ASME Section VIII Division 1 welding protocols

- Blockchain Traceability: Track raw material batches via our digital portal

- SIL 3 Support: Documentation packages for safety-critical systems

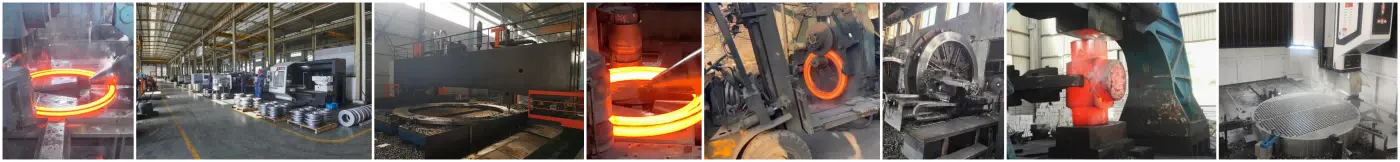

Quality Control

Factory Equipment

Shipping Packaging

FAQ: Your Top Questions Answered

Q: Can you match legacy flange designs from discontinued suppliers?

A: Yes – share drawings or samples, and we’ll replicate dimensions while upgrading materials if needed.

Q: How do you prevent flange face scratches during shipping?

A: We use multi-layer packaging – plastic caps over RTJ grooves, anti-abrasion foam, and steel-reinforced crates.

Q: Do you assist with orifice plate selection?

A: Absolutely. Our engineers provide FREE plate thickness/β-ratio calculations based on your flow parameters.

Q: What certifications accompany shipments?

A: Mill test reports, API 6A compliance certificates, and third-party inspection records (e.g., SGS/BV).

Contact Us

Need WN Orifice Flanges That Outlast Your Piping Systems?

📧 Contact Our Flow Experts Today:

Email: info@sxqinsteel.com

Learn about our latest products and discounts through SMS or email